Redefining Heavy-duty Handling

When Standard Isn’t Enough — Go Custom.

High-Capacity AGV & Handling Solutions, 2t – 800t overload capacity, Tailored to You.

OUR PROJECTS

Featured Case Studies by Industry

Machinery

Custom 15-Ton Battery-Powered Flatbed Transporter for Foundry Conditions | HENSEN

Heavy-Duty Electric Transfer Cart Solution for Metso’s China Foundry Not all factories are clean, automated, and modern. Many industrial sites—especially those involved in mining machinery, casting, and the production of heavy equipment spare parts—face dusty, uneven, and space-constrained environments. That’s exactly the kind of challenge HENSEN excels at solving. In this project, HENSEN delivered a customized 15-ton electric transport … Read more

Photovoltaic & Wind Energy

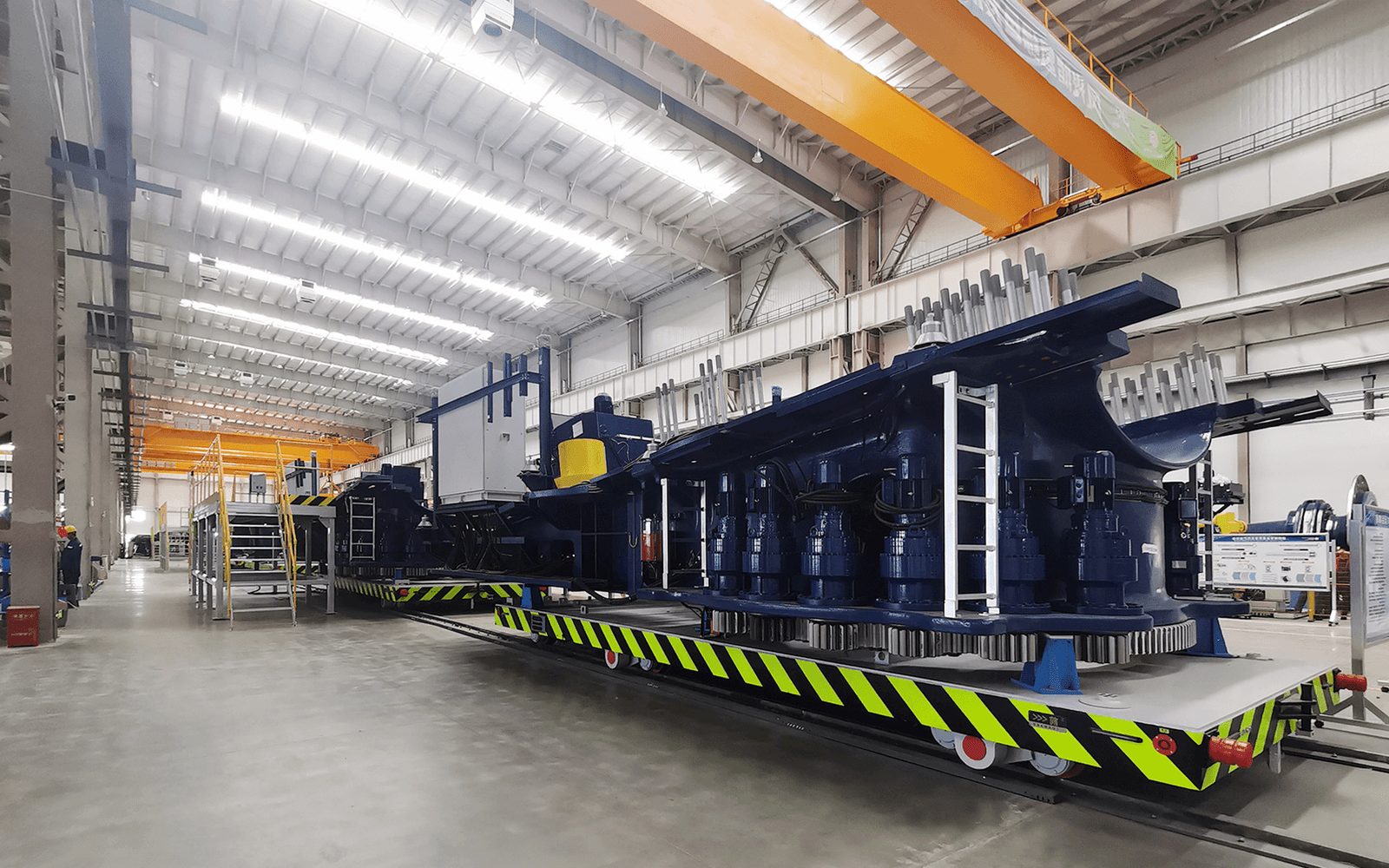

HENSEN Successfully Delivers 300-Ton Heavy-Duty AGV for Wind Power Industry

300-Ton Heavy-Duty AGV Successfully Tested and Delivered As autumn approaches, HENSEN’s passion for innovation remains strong. Recently, HENSEN completed performance testing of a customized 300-ton Heavy-Duty AGV and delivered it to the customer for operation. At HENSEN, our pride does not simply lie in the ability to customize AGVs with payload capacities of up to … Read more

Scientific & Aerospace

Custom-Engineered AGVs for High-Precision Scientific Transport – HENSEN Project Spotlight

One project is all it takes to show you what an AGV can truly achieve. •Multi-scenario application•High-level customization•Micron-level precision Project Background: Enabling Breakthroughs in Scientific Engineering HENSEN (Haosheng Electric Vehicles Co., Ltd.) participated in the development and delivery of smart AGV transport systems for a world-class scientific project: the Hard X-ray Free Electron Laser Facility, … Read more

Coating & Blasting

Custom 40 Ton Heavy-Duty AGV Solution for Oversized Pipeline Transport | HENSEN

If you’re also facing challenges in transporting extra-long pipelines or oversized industrial materials, especially under space limitations, complex workflows, or tight budget constraints, don’t worry, this real-world case study may offer the insights and inspiration you need. Project Overview: A leading pipeline manufacturer undertaking a major hydropower project turned to HENSEN for help. The project … Read more

Power & Electrical

AGV Applications in the Energy Storage Industry | HENSEN

Custom AGV Solutions for Battery Storage Manufacturing and System Integration Energy storage refers to the process of storing energy for later use in a controlled form. As countries accelerate their transition to clean energy, the energy storage industry—spanning battery cells, power systems, and grid-side applications—is experiencing explosive growth. HENSEN has become a trusted AGV partner … Read more

Precast Industry

Electric Transport Equipment for the Precast Concrete Industry | HENSEN

Custom Handling Solutions for Precast Components and Modular Construction Precast concrete, also known as PC components, refers to concrete structures manufactured in a factory setting through standardized, mechanized production. This contrasts with traditional cast-in-place concrete, which is molded, poured, and cured directly at the construction site. Precast concrete products are widely used in residential and … Read more

Injection Molding

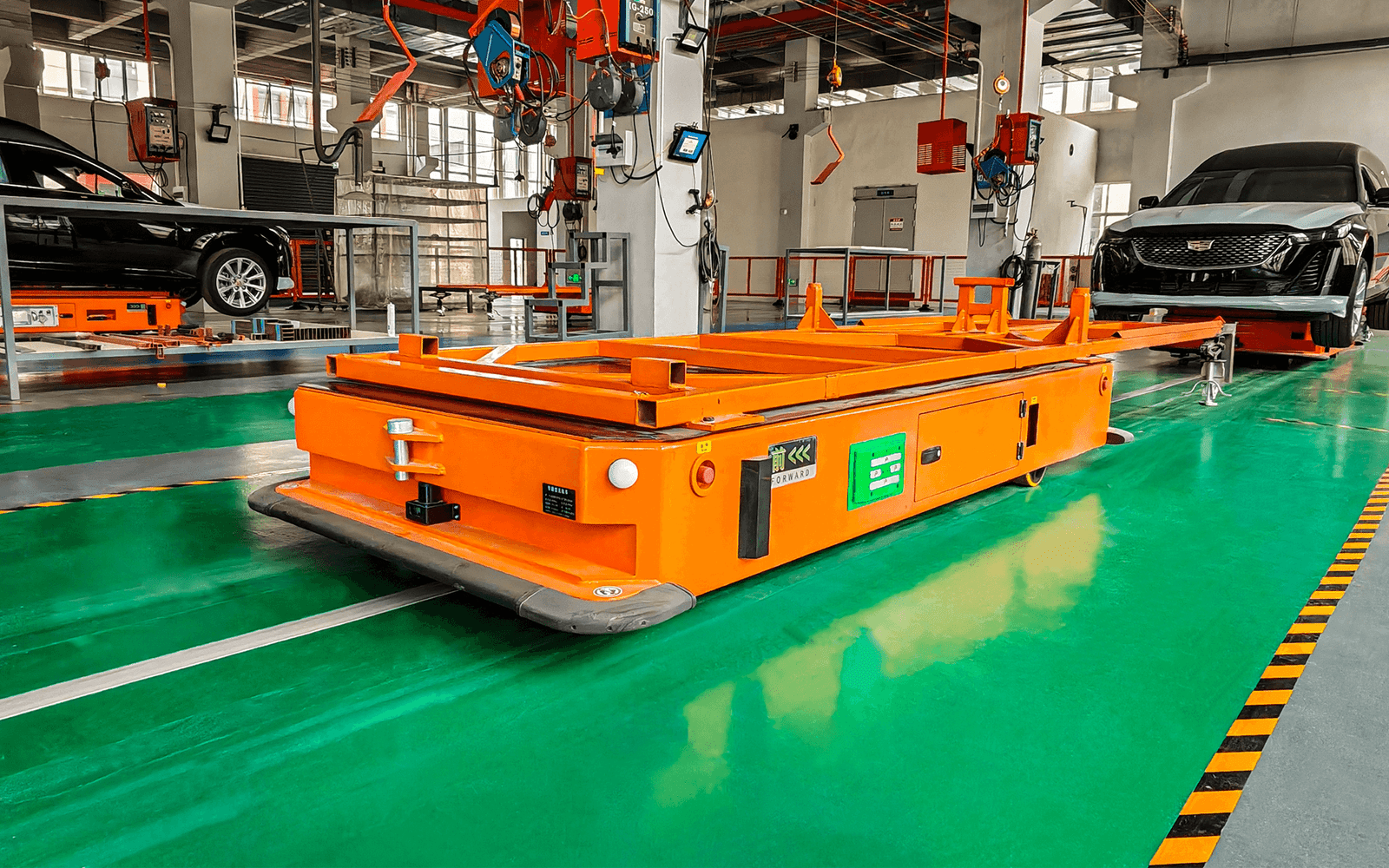

Intelligent RGV Transport System for Injection Molding Production Lines | HENSEN

Customized AGV/RGV Solutions for Efficient In-Plant Logistics In the world of large-scale industrial manufacturing, automated, safe, and space-efficient in-plant material handling is critical. Many manufacturers face the challenge of moving heavy components between production stages—especially in facilities with tight space constraints and high-frequency workflows. This is where HENSEN’s custom heavy-duty RGV and AGV transport solutions … Read more

WHO WE ARE

2005

Since

110

Certs & Patents

1010

Projects

150

Industries

HENSEN

A Leading Manufacturer

Specializing in battery-powered and intelligent heavy-duty transport systems, with nearly two decades of expertise in industrial mobility, we specialize in the research, design, and production of high-performance equipment for material handling and logistics automation.

OUR SERVICES

End-to-End Solutions for Your Toughest Challenges

Free Consultation

Understanding client requirements and operating conditions through an initial consultation. Clients complete our Parameters Inquiry Form to help us tailor a suitable solution.

In-House Design

Our pre-sales engineering team develops a detailed technical drawing based on the inquiry form. Once the design is approved by the client, we provide a formal quotation.

In-House Manufacturing

Upon order confirmation, production is scheduled at our facility. Vehicles with manual operation features are fully assembled and tested in-house before delivery.

Shipping & Logistics

After final inspection by the client, goods are shipped via sea or rail based on the client’s preference and project timeline.

Installation & Acceptance

For automated AGV projects, our technical service team provides on-site installation and commissioning. Final acceptance is conducted at the client’s facility.

After-Sales Policy

All equipment is covered by a one-year warranty. Beyond the warranty period, we offer paid repair and maintenance services to ensure long-term reliability.

LATEST NEWS

Factory Insights and Updates

Stay updated with the latest factory news, innovations, industry trends, and technological advancements in manufacturing.

Read MoreTESTIMONIALS

Voices Of Satisfied Clients

Hear from our satisfied clients about our factory’s R&D capabilities, quality, reliability, and exceptional service standards, as showcased in various project cases.

LET’S CLEAR THE AIR

Experience Quality With Us

We manufacture a wide range of in-plant transport vehicles, including:

•AGVs for automated production lines

•Auto-guided AGVs with magnetic or laser navigation

•Manually controlled AGVs with remote operation

•Trackless transfer carts (WPX series)

•Battery-powered electric transport vehicles (BD series)

•All products are designed for safe, efficient, and customizable material handling within industrial environments.

We implement rigorous quality control processes, including inspections, testing, and certifications, to ensure all products meet clients’ requirements and industry standards.

Our typical production lead time is 6–8 weeks.

However, the exact timeline may vary depending on the size and complexity of the project. We’ll confirm a detailed schedule after evaluating your specific requirements.

Absolutely — customization is our core strength.

We have a dedicated R&D team, an experienced production team, and over 20 years of industry know-how. To date, we’ve delivered 1,000+ customized projects across 150+ industries, providing tailored solutions that meet unique operational needs.

Yes, we provide overseas installation services for projects where on-site setup and commissioning are essential—particularly for automated production line AGV systems.

For projects that do not require on-site installation, such as manually controlled AGVs, we offer complete in-factory testing and remote acceptance via video demonstration or third-party inspection arranged by the customer.

Final arrangements are made based on mutual agreement to ensure efficiency and cost-effectiveness.

LET’S GET STARTED

Contact Us For Manufacturing Solutions

Contact us to discuss your

custom solution.

-Address

158 Ganxiao Road

Qingshanhu Tech City

Lin’an, Hangzhou-China